Originally Direct from the U.S. NAVY Joint Services P2 Maintenance on-line public files

Maintenance Guide @ http://p2library.nfesc.navy.mil/P2_Opportunity_Handbook/6_II_1.html

Website no longer exists.

New Location @ http://infohouse.p2ric.org/ref/20/19926/p2_opportunity_handbook/6_II_1.html

This Link no longer good.

PDF Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

OVERVIEW:

By-Pass Filtration = Super Filters Motor Oil Keeping It Analytically Clean

Automotive experts agree that dirt is the number one cause of engine wear. Compared to microscopic dirt particles, your engine is a Goliath, roaring with heat and energy as it converts fuel into raw horsepower.

But despite all this power, your engine is extremely vulnerable to the threat of microscopic engine dirt. In fact, if unchecked, this tiny menace will dramatically erode your engine's performance and can eventually cripple it beyond repair.

|

|

|

By-Pass filtration is a valuable commodity for anyone that wants to extend drain intervals and prolong engine life. It is also beneficial to vehicles that are exposed to high levels of contaminants on a regular basis. They provide the ultimate in protection against wear, oil degradation, rust and corrosion. Efficiency is the filter's ability to capture contaminants.  The more efficient a filter is, the more contaminants it will remove from the oil. The more efficient a filter is, the more contaminants it will remove from the oil.

|

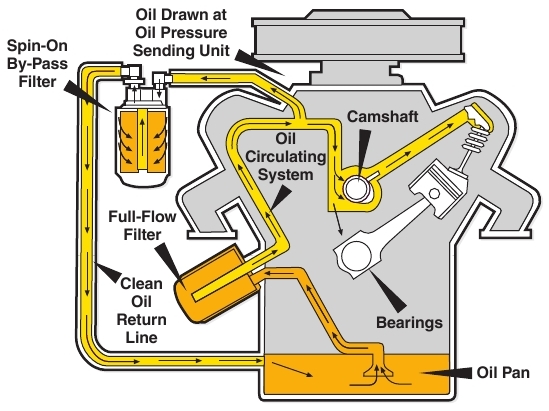

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.

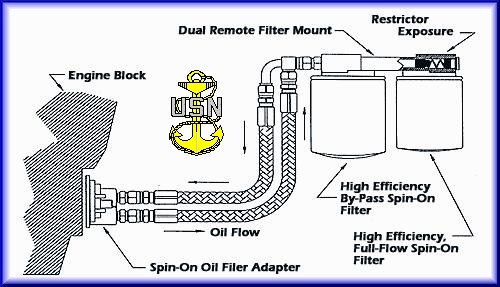

By-Pass Filters reduce engine wear and increase oil volume, but their high efficiencies mean they also have higher restriction and must be used in conjunction with a full-flow filter.

By-Pass Filters operate by filtering oil on a "partial-flow" basis. They draw approximately 10 percent of the oil pump's capacity at any one time and trap the extremely small, wear-causing contaminants that full-flow filters can't remove.

By-Pass Filters have a high pressure differential, causing the oil to flow through them very slowly and allowing for the removal of smaller contaminants. It is called By-Pass filtration because the oil flows from the By-Pass filter back to the sump and By-Passes the engine.

This continual process will eventually make all of the oil analytically clean, reduces long-term wear and can extend oil change drain intervals.

This continual process will eventually make all of the oil analytically clean, reduces long-term wear and can extend oil change drain intervals.

|

By-Pass Oil Filtration Benefits By-Pass Oil Filtration Benefits

- Significantly Extended Engine Life

- Efficient Removal of Small Particles and Soot

- Removal of Particles Less Than One Micron

- Increased Engine Efficiency

- Improved Oil Cooling

- Helps Maintain Oil Viscosity

- Reduces Unscheduled Downtime

- Reduces Operational Costs

- Increased Fluid System Capacity

- Increased Filtration Capacity and Life

- Environmentally Friendly

- Extended Drain Intervals

|

By-Pass Filters are designed to remove smaller particulates than would be removed by an engine's normal full-flow filter, so that the need for additional oil or oil changes can be reduced.

By-Pass Filtration retains the oil longer and does a more thorough job of removing contaminants without obstructing flow. By-Pass Filtration units allows larger oil filters to be used, and increases oil sump capacity - dramatically extending the oil's and engine's useful service life.

High Density By-Pass Filtration extends the useful life of oils and engines. In addition to reducing waste oil generation, collateral benefits include reduced acquisition of motor oil lubricants, reduced labor hours in the management of waste oil, and an extension of engine life through improved lubrication.

Removes Water  Automobile engines are also susceptible to damage related to water formation, something a full-flow filter is powerless against. Water enters the oil either as a blowby combustion product of fuel ignition, or as condensed moisture from air drawn into the engine through the carburetor. Water causes metal surfaces to rust; it also reacts with other blowby contaminants to produce corrosive acids that attack the engine, contributing to further friction, wear, debris, and oil degradation.

Automobile engines are also susceptible to damage related to water formation, something a full-flow filter is powerless against. Water enters the oil either as a blowby combustion product of fuel ignition, or as condensed moisture from air drawn into the engine through the carburetor. Water causes metal surfaces to rust; it also reacts with other blowby contaminants to produce corrosive acids that attack the engine, contributing to further friction, wear, debris, and oil degradation.

Some solid contaminants (dirt, wear particles, etc.) lead to abrasion and wear (rings, liners, cam, bearings, etc). Other contaminants (soot, sludge, oxide insolubles, glycolic compounds, etc.) can contribute to deposition formation in the combustion zone (crown land, ring lands, skirt) and valve area (valve seats/guides) of the engine.

These deposits can also contribute to wear and combustion efficiency problems with engines. Recent studies on the contaminant sensitivity of engines have found all of these solid contaminants to be important to engine reliability and efficient operation (relating to emissions, fuel economy, oil consumption, etc.). These contaminants are typically suspended in crankcase lubricants in sizes ranging from submicron to more than 100 microns.

Typically the very best full-flow filters exhibit a capture efficiency of 50 percent at particle sizes 10-microns and above. Smaller soot suspension and polar insolubles that can also cause wear and deposits are not controlled by these full flow filters effectively. For this reason, compressed cellulose depth media used as by-pass filters can offer benefits in removing fine organic and inorganic particles. In combination with full- flow filters the benefits can be lower wear, lower oil consumption, higher combustion efficiency, and longer oil life. There are a variety of by-pass filters on the market including centrifugal separators.

Things to consider when buying a By-Pass Filter include pressure vs. flow (P-Q), Beta or capture efficiency at say 3 microns, 6 microns and 15 microns, and dirt-holding capacity. If the filter supplier has tested it's by-pass filter to standard procedures such as SAE J1858, ISO 4548 or ISO 16889 this information would be available.

By-Pass Filters also increase the total volume of oil used by the engine. This means that more oil additives are available as well as fluid volume to dilute the concentration of contaminants.

By-Pass Filters also increase the total volume of oil used by the engine. This means that more oil additives are available as well as fluid volume to dilute the concentration of contaminants.

PDF  Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

ALSO: Machinery Lubrication Magazine - Practicing Oil Analysis

There are many ways that a lubricant could fail to deliver fuel-efficient engine performance.

Clean Engine Oil = Better Vehicle Fuel Economy and Reduced Vehicle Emissions