Is your business looking for a competitive advantage... Consider the fact U.S. Military Veterans have access to advanced cutting edge technology sometimes decades before the civilian sector...

For 35 + Years the Best Kept U.S. Military Vehicle Maintenance SECRET

For 35 + Years the Best Kept U.S. Military Vehicle Maintenance SECRET

Solve or Eliminate Some Costly and Time-Intensive Vehicle Maintenance Procedures

Solve or Eliminate Some Costly and Time-Intensive Vehicle Maintenance Procedures

|

In Maintenance, LESS means MORE In Maintenance, LESS means MORE

LESS Effort means MORE Productivity

LESS Complicated means MORE Confidence

LESS Waste means MORE Profit (REDUCED Expenses)

|

Wasted vehicle maintenance material, motion and time, drastically affect YOUR bottom-line...

Wasted vehicle maintenance material, motion and time, drastically affect YOUR bottom-line...

|

REDUCE Equipment Down or Out of Service Time REDUCE Equipment Down or Out of Service Time

REDUCE Lubricant Inventory Requirements REDUCE Lubricant Inventory Requirements

ELIMINATE Premature Equipment Failures ELIMINATE Premature Equipment Failures

REDUCE Fuel and Energy Consumption REDUCE Fuel and Energy Consumption

REDUCE Hazardous Waste Lubricants REDUCE Hazardous Waste Lubricants

STREAMLINE Maintenance Protocols STREAMLINE Maintenance Protocols

|

REDUCE Waste Disposal Expenses REDUCE Waste Disposal Expenses

REDUCE Man Hour Requirements REDUCE Man Hour Requirements

MAXIMIZE Equipment Service Life MAXIMIZE Equipment Service Life

EXTEND Lubricant Drain Intervals EXTEND Lubricant Drain Intervals

REDUCE Capital Expenditures REDUCE Capital Expenditures

INCREASE Production INCREASE Production

|

Most vehicles can run 500,000 to 1 million miles without engine, transmission, or differential failures.

Most vehicles can run 500,000 to 1 million miles without engine, transmission, or differential failures.

U.S. Navy Engineers Do MORE Maintenance with LESS

U.S. Navy Engineers Do MORE Maintenance with LESS

For 35 + Years the Best Kept U.S. Military Vehicle Maintenance SECRET

Originally: Direct from the U.S. NAVY Joint Services P2 Maintenance On-Line Public Files

3-Steps to Drastically Reduce Vehicle Maintenance Time Requirements and Maximize Life Cycle

|

U.S. Military Engineering NOTE: The Service Life Cycle of a Lubricant... Is dependent upon the "QUALITY" of the oil and the filtration system's ability to keep it clean.

Step # 1 Super Filters Motor Oil Keeping It Analytically Clean Step # 2 For MAXIMUM Protection and Extended Oil Change Drain Intervals Step # 3 The Final Safe Guard to Eliminate The Guess Work on Engine and Oil Condition

|

Maximize oil change drain intervals without risking reliability. You will get better wear protection, lower engine operating temperatures, improved fuel efficiency (MPG) and easier cold-weather starts. All of these benefits add up to reduced operating costs and longer engine life. And even more, you generate less waste oil, which helps preserve our environment and reduce our dependence on foreign oil.

Backed-Up by 1995 Society of Automotive Engineers Technical Paper #952553

The Society of Automotive Engineers (SAE) is the premiere world resource for the design, manufacturing, operation, and maintenance of automobiles, aircraft, space vehicles, off-highway equipment, trucks, buses, trains, marine craft, engines, and self-propelled vehicles.

The largest automotive and aerospace standards-setting body in the world, SAE offers technical information in the form of papers, books, magazines, meetings, conferences, professional development seminars, workshops, expositions, continuing education programs, and Internet products. SAE is committed to serving Society through its vehicle safety, maintenance, resource conservation, and education programs.

Step # 1 of 3 By-Pass Filtration = Super Filters Motor Oil Keeping It Analytically Clean

Step # 1 of 3 By-Pass Filtration = Super Filters Motor Oil Keeping It Analytically Clean

|

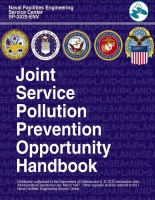

Originally Direct from the U.S. NAVY Joint Services P2 Maintenance on-line public files

Maintenance Guide @ http://p2library.nfesc.navy.mil/P2_Opportunity_Handbook/6_II_1.html

Website no longer exists.

New Location @ http://infohouse.p2ric.org/ref/20/19926/p2_opportunity_handbook/6_II_1.html

This Link No Longer Good.

PDF Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

|

Overview:

By-Pass Filtration = Super Filters Motor Oil Keeping It Analytically Clean

Automotive experts agree that dirt is the number one cause of engine wear. Compared to microscopic dirt particles, your engine is a Goliath, roaring with heat and energy as it converts fuel into raw horsepower.

But despite all this power, your engine is extremely vulnerable to the threat of microscopic engine dirt. In fact, if unchecked, this tiny menace will dramatically erode your engine's performance and can eventually cripple it beyond repair.

|

|

|

By-Pass filtration is a valuable commodity for anyone that wants to extend drain intervals and prolong engine life. It is also beneficial to vehicles that are exposed to high levels of contaminants on a regular basis. They provide the ultimate in protection against wear, oil degradation, rust and corrosion. Efficiency is the filter's ability to capture contaminants.  The more efficient a filter is, the more contaminants it will remove from the oil. The more efficient a filter is, the more contaminants it will remove from the oil.

|

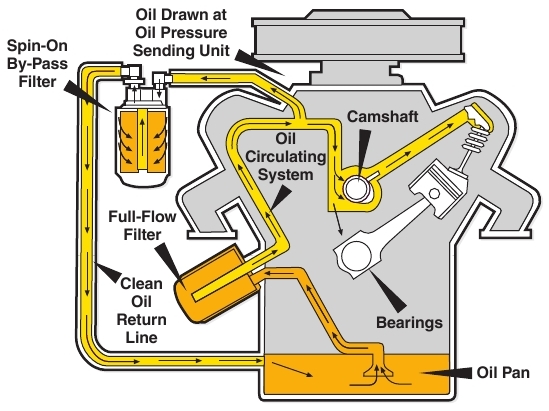

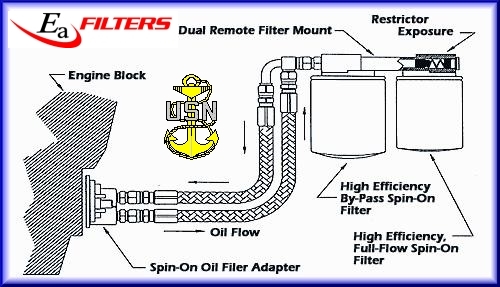

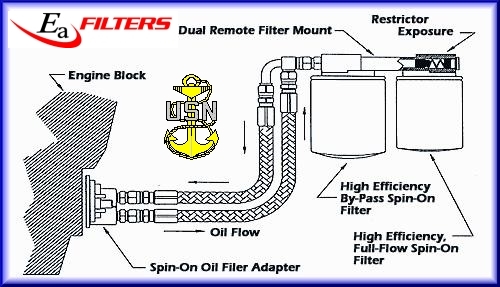

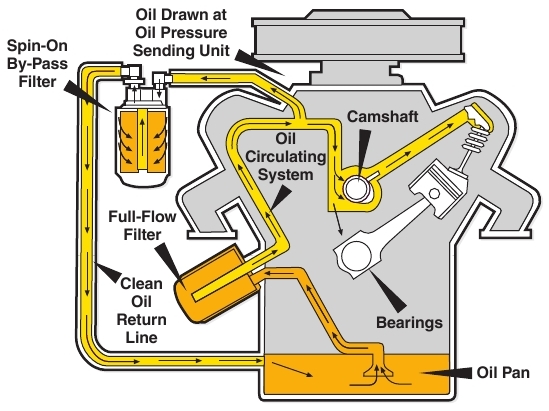

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.

By-Pass Filters reduce engine wear and increase oil volume, but their high efficiencies mean they also have higher restriction and must be used in conjunction with a full-flow filter.

By-Pass Filters operate by filtering oil on a "partial-flow" basis. They draw approximately 10 percent of the oil pump's capacity at any one time and trap the extremely small, wear-causing contaminants that full-flow filters can't remove.

By-Pass Filters have a high pressure differential, causing the oil to flow through them very slowly and allowing for the removal of smaller contaminants. It is called By-Pass filtration because the oil flows from the By-Pass filter back to the sump and By-Passes the engine.

This continual process will eventually make all of the oil analytically clean, reduces long-term wear and can extend drain intervals.

This continual process will eventually make all of the oil analytically clean, reduces long-term wear and can extend drain intervals.

|

By-Pass Oil Filtration Benefits By-Pass Oil Filtration Benefits

- Significantly Extended Engine Life

- Efficient Removal of Small Particles and Soot

- Removal of Particles Less Than One Micron

- Increased Engine Efficiency

- Improved Oil Cooling

- Helps Maintain Oil Viscosity

- Reduces Unscheduled Downtime

- Reduces Operational Costs

- Increased Fluid System Capacity

- Increased Filtration Capacity and Life

- Environmentally Friendly

- Extended Drain Intervals

|

By-Pass Filters are designed to remove smaller particulates than would be removed by an engine's normal full-flow filter, so that the need for additional oil or oil changes can be reduced.

By-Pass Filtration retains the oil longer and does a more thorough job of removing contaminants without obstructing flow. By-Pass Filtration units allows larger oil filters to be used, and increases oil sump capacity - dramatically extending the oil's and engine's useful service life.

High Density By-Pass Filtration extends the useful life of oils and engines. In addition to reducing waste oil generation, collateral benefits include reduced acquisition of motor oil lubricants, reduced labor hours in the management of waste oil, and an extension of engine life through improved lubrication.

Removes Water  Automobile engines are also susceptible to damage related to water formation, something a full-flow filter is powerless against. Water enters the oil either as a blowby combustion product of fuel ignition, or as condensed moisture from air drawn into the engine through the carburetor. Water causes metal surfaces to rust; it also reacts with other blowby contaminants to produce corrosive acids that attack the engine, contributing to further friction, wear, debris, and oil degradation.

Automobile engines are also susceptible to damage related to water formation, something a full-flow filter is powerless against. Water enters the oil either as a blowby combustion product of fuel ignition, or as condensed moisture from air drawn into the engine through the carburetor. Water causes metal surfaces to rust; it also reacts with other blowby contaminants to produce corrosive acids that attack the engine, contributing to further friction, wear, debris, and oil degradation.

Some solid contaminants (dirt, wear particles, etc.) lead to abrasion and wear (rings, liners, cam, bearings, etc). Other contaminants (soot, sludge, oxide insolubles, glycolic compounds, etc.) can contribute to deposition formation in the combustion zone (crown land, ring lands, skirt) and valve area (valve seats/guides) of the engine.

These deposits can also contribute to wear and combustion efficiency problems with engines. Recent studies on the contaminant sensitivity of engines have found all of these solid contaminants to be important to engine reliability and efficient operation (relating to emissions, fuel economy, oil consumption, etc.). These contaminants are typically suspended in crankcase lubricants in sizes ranging from submicron to more than 100 microns.

Typically the very best full-flow filters exhibit a capture efficiency of 50 percent at particle sizes 10-microns and above. Smaller soot suspension and polar insolubles that can also cause wear and deposits are not controlled by these full flow filters effectively. For this reason, compressed cellulose depth media used as by-pass filters can offer benefits in removing fine organic and inorganic particles. In combination with full- flow filters the benefits can be lower wear, lower oil consumption, higher combustion efficiency, and longer oil life. There are a variety of by-pass filters on the market including centrifugal separators.

Things to consider when buying a By-Pass Filter include pressure vs. flow (P-Q), Beta or capture efficiency at say 3 microns, 6 microns and 15 microns, and dirt-holding capacity. If the filter supplier has tested its by-pass filter to standard procedures such as SAE J1858, ISO 4548 or ISO 16889 this information would be available.

By-Pass Filters also increase the total volume of oil used by the engine. This means that more oil additives are available as well as fluid volume to dilute the concentration of contaminants.

By-Pass Filters also increase the total volume of oil used by the engine. This means that more oil additives are available as well as fluid volume to dilute the concentration of contaminants.

PDF  Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

Step # 1 of 3 = Bypass Filter for Vehicle Motor Oil - Chapter # 6-II-1

ALSO: Machinery Lubrication Magazine - Practicing Oil Analysis

There are many ways that a lubricant could fail to deliver fuel-efficient engine performance.

Clean Engine Oil = Better Vehicle Fuel Economy and Reduced Vehicle Emissions

Step # 2 of 3 Synthetic Motor Oil = MAXIMUM Protection and Extended Oil Drain Intervals

Step # 2 of 3 Synthetic Motor Oil = MAXIMUM Protection and Extended Oil Drain Intervals

Overview:

Synthetic Motor Oil = MAXIMUM Protection and Extended Oil Drain Intervals

When used in place of conventional motor oil, synthetic oil lasts longer thus requiring fewer change outs. As a result, both waste oil generation and consumption of oil are reduced.

Synthetic oils have high resistance to changes in viscosity due to temperature, and thus have less of a requirement for thickeners. As such they provide a heavier, more stable protective oil film for engine bearings and piston rings than that provided by similar SAE-grade mineral oils.

The U.S. Military has used Advanced Synthetic Lubrication Technology for Decades

WHY Does Every Jet Fighter Engine in The World use Synthetic Lubricants Exclusively?

Because of three extraordinary high-performance characteristics...

Because of three extraordinary high-performance characteristics...

1. With an ability to reduce friction and wear on engine components

2. With an ability to function dependably at severe temperature extremes

3. With an ability to withstand rigorous and lengthy engine operation without chemical breakdown

The Bottom Line: Only synthetic lubricants superb hi-performance and protection can stand up to the "extreme" heat and cold temperatures and high rpm performance operating conditions of jet fighter engines.  Those same outstanding performance benefits synthetic lubricants provide for jet fighter engines prove invaluable to car, truck and other internal combustion engines.

Those same outstanding performance benefits synthetic lubricants provide for jet fighter engines prove invaluable to car, truck and other internal combustion engines.

Vehicle and Equipment failures occur for a variety of reasons. Each one of these failures creates a ripple effect of costs and productivity loss. Some of these issues can be mitigated by choosing a high performance synthetic lubricant that can withstand harsh/extreme operating conditions and/or environments and ultra-fine filtration. While high performance synthetic lubricants and ultra-fine filtration are more expensive initially, the added expenditure is recovered through reduced breakdowns, downtime and maintenance costs, which results in long-term overall savings.

PDF  Step # 2 of 3 = Substituting Synthetic Oil for Conventional Oil - Chapter # 6-II-4

Step # 2 of 3 = Substituting Synthetic Oil for Conventional Oil - Chapter # 6-II-4

Society of Automotive Engineers (SAE) Documented Synthetic Motor Oils Go The 100,000-Miles + Distance

Society of Automotive Engineers (SAE) Documented Synthetic Motor Oils Go The 100,000-Miles + Distance

Society of Automotive Engineers 1995 Technical Paper #952553

"A Synthetic Diesel Engine Oil with Extended Laboratory Test and Field Service Performance." describes engine test and "extended oil drain" field performance of a synthetic 5w-40 motor oil with "an additive system specifically formulated for synthetic basestocks" made for use in North American low-emissions heavy-duty engines.

SAE Researchers found, "Many units have operated on [ the synthetic oil ] in heavy-duty, long haul service at "extended drain intervals" with some units on drain intervals BEYOND 100,000-Miles. Even under these conditions [ the synthetic oil ] has consistently provided measurable benefits in terms of improved engine performance".

For a reprint of Society of Automotive Engineers 1995 Technical Paper #952553

Or Call 1 . 8 7 7 . 6 0 6 . 7 3 2 3

Beat the Heat Reduce Operating Temperatures

Beat the Heat Reduce Operating Temperatures

Whether it is ambient or generated or a combination of both. Reduce operating temperatures of bearings, transmissions, gearboxes, engines and hydraulic unit's etc. 20 to 50 degrees using synthetic lubricants.

Did YOU Know: Rigid conventional petroleum lubricant motor oil molecules move heat along hot surfaces? The surface of the oil film gets overburdened with heat while the core of the oil stream gets a free ride. It's called Laminar Flow, it is not an efficient system, and it keeps engine surfaces HOTTER.

YET: Synthetic motor oils are better heat transfer agents than conventional petroleum lubricants are, so the engines heat bill adds up to less. Flexible synthetic lubricant lubricant oil molecules allow heat to swirl away from the hot surfaces and into the core of the oil stream. It's called Turbulent Flow.

Not All Synthetics are Created Equal.

The QUALITY-FIRST Original - Inspired by Aerospace Technology

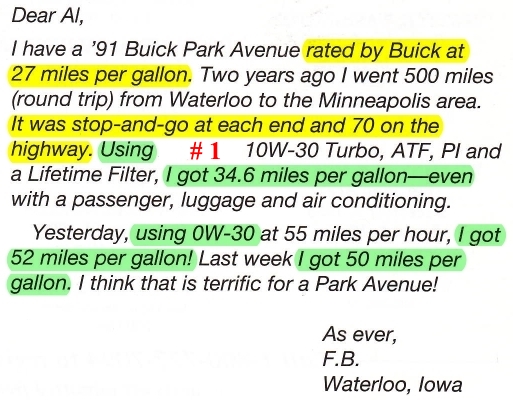

1995 Independent Lab Fuel Efficiency Testing of advanced quality-first formulated 35,000-Mile/1-Year 0W-30 Synthetic Motor Oil showed the oil provided 38% better fuel economy than required for the specification. That was the largest fuel economy increase recorded by the test lab. Its ULTRA Low Coefficient of Friction reduces friction so effectively, that virtually none of the engines power is wasted on “drag”.

1995 Independent Lab Fuel Efficiency Testing of advanced quality-first formulated 35,000-Mile/1-Year 0W-30 Synthetic Motor Oil showed the oil provided 38% better fuel economy than required for the specification. That was the largest fuel economy increase recorded by the test lab. Its ULTRA Low Coefficient of Friction reduces friction so effectively, that virtually none of the engines power is wasted on “drag”.

Step # 3 of 3 Oil Analysis = Eliminate The Guess Work on Engine and Oil Condition

Step # 3 of 3 Oil Analysis = Eliminate The Guess Work on Engine and Oil Condition

|

Originally Direct from the U.S. NAVY Joint Services P2 Maintenance on-line public files

Maintenance Guide @ http://p2library.nfesc.navy.mil/P2_Opportunity_Handbook/6_II_3.html

Website no longer exists.

New Location @ http://infohouse.p2ric.org/ref/20/19926/p2_opportunity_handbook/6_II_3.html

This Link No Longer Good.

PDF  Step # 3 of 3 = Lubricant Analysis Programs - Chapter # 6-II-3 Step # 3 of 3 = Lubricant Analysis Programs - Chapter # 6-II-3

|

Overview:

Oil Analysis = Eliminate The Guess Work on Engine and Oil Condition

A Proven Industry Standard Maintenance Tool! Minimize Wear and Maximize Productivity. Contaminants that can indicate wear or cause serious equipment damage such as metals, water, raw fuel, acids, fuel soot and other solids collect in your lubricant.

Using oil analysis to evaluate these contaminants is a scientific approach to predictive maintenance, allowing you a look inside your machinery to spot mechanical wear and contamination in its early stages.

You'll extend machine life, head off major maintenance costs and prevent catastrophic failure that can shut you down or leave you stranded, and you'll maximize lubricant life.

|

Keep in mind these general goals for an oil analysis program:

- Optimize machine reliability, productivity and profitability.

- Reduce cost of maintenance.

- Minimize safety risks or related hazards.

- Reduce friction, heat and energy consumption.

- Reduce fluid consumption.

- Reduce fluid disposal/environmental impact.

- Improve product quality.

- Detect operator abuse/error.

- Optimize the selection of fluids used.

- Detect improper machine installation/repairs.

|

PDF  Step # 3 of 3 = Lubricant Analysis Programs - Chapter # 6-II-3

Step # 3 of 3 = Lubricant Analysis Programs - Chapter # 6-II-3

ALSO:  EPA Oil Life Extension Program

EPA Oil Life Extension Program

https://www.epa.gov/sites/production/files/2016-02/documents/fleet_oil.pdf

Knowledge Shared is Power Multiplied

Butch (Chief) McKenzie

TEXT Message # 256.792.8181

P.O. Box # 273, Cedar Bluff, AL. 35959-0273

Thank You for Visiting My Website... Chief

U.S. Navy 1964-1991

1964-1991

MMC (SW) Retired

U.S.S. Iowa BB-61 Battleship Engineer 1983-1988

U.S. Navy Engineers Do MORE Maintenance with LESS

1964-1991

1964-1991

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.

By-Pass Oil Filtration is a secondary filter with the purpose of eliminating nearly all contaminants in engine oil. They have high capacities and eliminate much smaller particles than full-flow filters, including soot.